Near the Alewife station in Cambridge, there’s a quiet industrial area with some small-to-medium sized offices. On the southeast end lives Soft Robotics, a company doing great things for the food, beverage, advanced manufacturing, and eCommerce industries.

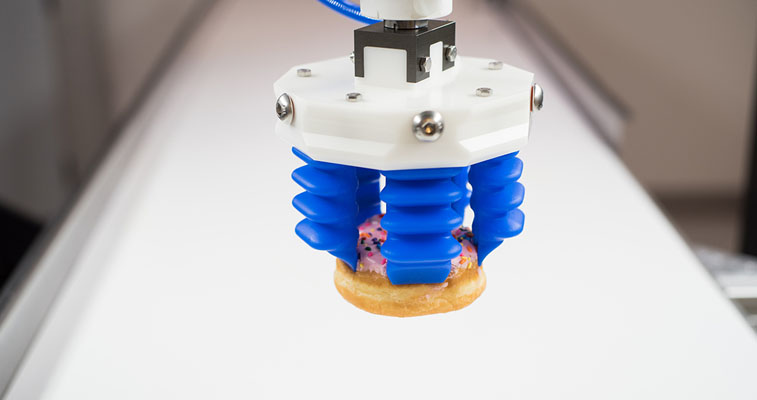

Soft Robotics’ machines are built from a proprietary and versatile material which, through material science, enables a robot to grasp and manipulate items of varying size, shape, and weight.

These features were initially theorized back in 2008 when DARPA began a robotics research project called Chembot.

“DARPA asked various research groups across the country, ‘Could you build a robot that can walk up to a door, get itself under the door, and then walk away from it?’” says Soft Robotics CEO Carl Vause. “Several traditional robotics groups, like iRobot, received funding to solve this problem, but there was a group out of Harvard that also received funding.”

Harvard’s Whitesides Research Group began to examine DARPA’s question, not from a mechanical standpoint, but a biological one. Using observations on how an octopus can morph its body to fit underneath rocks in the ocean, the group decided to apply that to robotics. The robot was built entirely out of elastomeric materials, and would undergo a transformation process the group named “morphological computation.” Whitesides Research Group went to work and began experimenting with this new process.

Their experiment proved to be successful, and the group received $400,000 in DARPA funding, to be placed into future projects. In 2013, they spun off to their own company called Soft Robotics.

The robots resemble high-tech claw machines, but their grippers aren’t hard metal, as the company started using the same soft material for their DARPA experiment. A major focus on the manufacturing side was to give the robots a black-and-white vision of what it can and cannot grab. The robots were developed with a sophisticated system to give customers full control of the grip parameters, such as speed, force, gripper spacing, and opening width.

When the company became its own, they initially made prototypes for Boston-area hospitals such as Brigham and Women’s. However, the company realized that their biggest market opportunity was in industrial automation.

“Robots today are great when it comes to hard labor, such as painting or welding a car,” Vause says. “They aren’t necessarily great at grabbing soft objects. We thought, ‘How can you build something that can grasp and package objects like a human hand?’”

Soft Robotics pivoted and started focusing on the automation industry. Vause and the company began to examine the industry at large and found some interesting findings.

Companies like Amazon have a large demand for labor in order to keep up with the thousands of orders they receive. “The average age of a worker in manufacturing is 46 and there is a declining workforce,” the Soft Robotics CEO says. “In the food and beverage industry, there are food safety issues with human-transferred pathogens.”

Many CPG and eCommerce companies are using Soft Robotics for their food products, in packaging applications that range from raw pizza dough to fresh produce. Thanks to the unique manufacturing of the system, the robot’s grippers do not squish or damage the food.

The company is currently a team of 24, but they are always looking for new members interested in the robotics industry.

Colin Barry is a contributor to VentureFizz. Follow him on Twitter @ColinKrash.